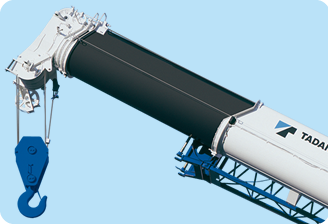

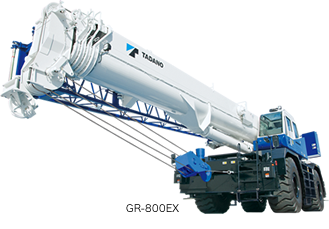

The rounded boom is made of high tensile steel, which allows for decreased boom weight and increased boom strength.

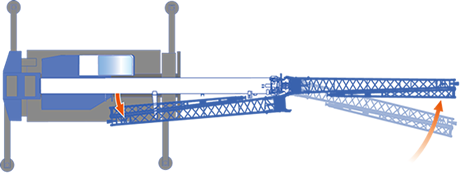

When mounting and stowing the jib, the assist hydraulic cylinders are used resulting in increased work efficiency and safety.

Jib installation (Bi-fold Jib)

The operator has enhanced capabilities with two boom telescoping options whichever suits the lift needs.

Mode Ⅰ is extension of 2nd section only. Then follows the synchronized extension of 3rd, 4th and 5th sections.

Mode Ⅱ is synchronized extension of 3rd, 4th and 5th sections. Then 2nd section extends independently.

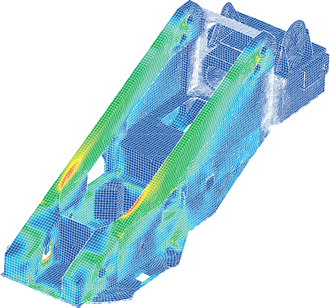

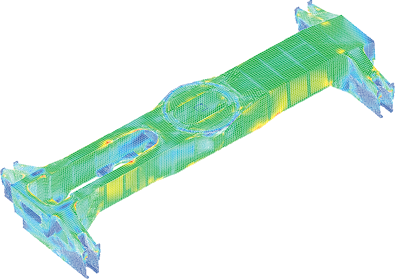

During development of the structural shape of the crane,

*FEM analysis was applied to achieve a design tailored for optimal operation. The slewing frames’ structure ensures a highly rigid, compact style that is well suited for the overall planned design of the crane.

*FEM: Finite Element Method

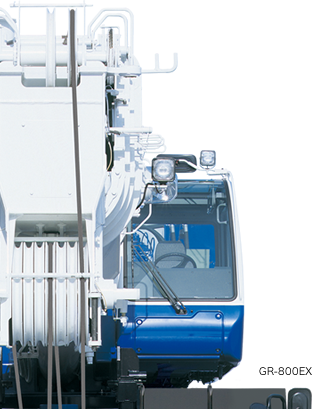

The crane cab provides improved livability and a more comfortable working environment.

Both the main winch and the auxiliary winch have powerful line pull and operate at high speeds thus enhancing work efficiency.

*Maximum permissible line pull may be affected by wire rope strength.

Folding mirror reduces height during transport.

When operating the crane with the asymmetric outriggers extended, the AML-C detects the extension width of all of the Crane's outriggers (front, rear, left and right) to measure maximum work capacity in each area.

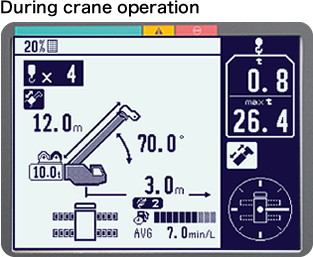

Tadano’s AML-C is easy to use, innovative in design, displays important information to the operator and enables the operator to preset a custom working environment. For example, the AML-C shows the boom angle, boom length, load radius, operating pressure of the elevating cylinder, the extension width of the outriggers, slewing position, rated lifting capacity and present hook load. These features allow the AML-C to move seamlessly through all lifting operations without having to change configurations or input new codes to make the lift.

The AML-C safety features provide both audible and visual warnings.

When an operation approaches the load limit Tadano’s slow stop function engages to avoid shock loads.

The new carrier frame design was developed and built so that its lightweight is compatible with its high rigidity to achieve an advanced level of performance. As a result, the rigidity was enhanced by as much as *35% which enables highly stabilized maneuverability for the new model of crane.

*Compared with our conventional crane models

Increased engine durability.

Hydraulic power steering.

The Fuel Monitoring System constantly monitors fuel consumption on the AML screen. Checking this monitor enables you to prevent wasteful fuel consumption from unnecessary acceleration and idling.

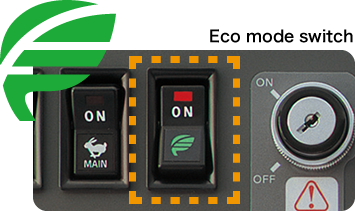

The Eco Mode System controls the maximum engine speed at the time of crane operation.

To prevent an unnecessary rise in engine speed when there is excessive acceleration, the system enables fuel consumption and CO2 emissions to decrease by Max. 22%with Eco mode 1, and Max. 30% with Eco mode 2, and the noise level is reduced.

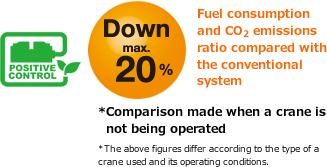

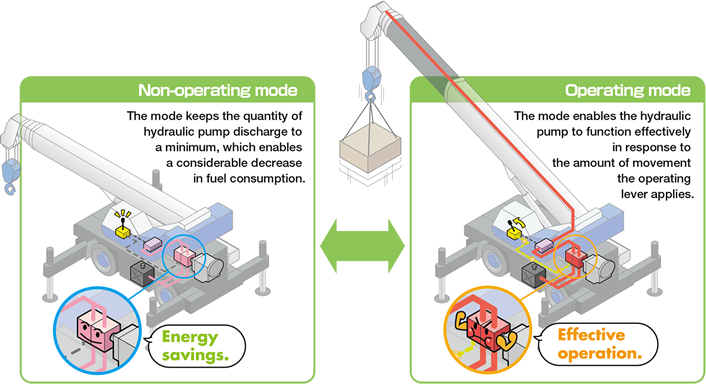

The Positive Control System effectively controls the quantity of hydraulic pump discharge during crane operation in response to the amount of movement applied by the operating control lever. When the crane is in a state of idling, the Positive Control System keeps the quantity of hydraulic pump discharge to a minimum, reducing fuel consumption and CO2 emissions by up to 20%.

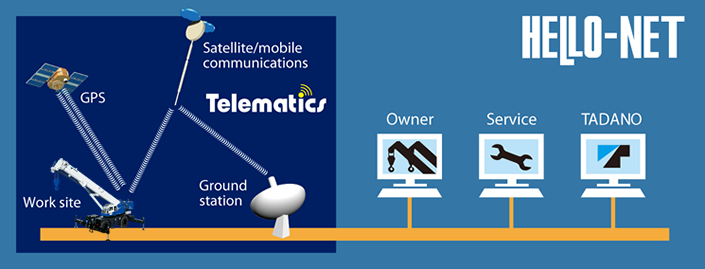

The HELLO-NET System is used to monitor crane activity straight from your computer or mobile device.

You have the ability to view work history, machine position data and maintenance information.

HELLO-NET provides advanced customer support between the owners' site and TADANO Group.

Note: HELLO-NET availability varies by situation. For detail, please contact your distributor or our sales staff in charge.