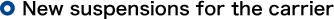

The carrier has been newly designed, right down to the suspension, to pass long and

rigorous road tests in a variety of environments and substantially improve crane mobility.

The cabin has also been remodeled with features that contribute to comfortable

and safe driving, such as automatic mechanical transmission.

The ride quality has been optimized to ensure the driver's comfort

and protect the carrier.

Sachs shock absorbors

Improved ride comfort and operability.

Featuring rubber suspension co-developed

with Hendrickson

Extreme durability proven in the harshest

environments.Improved ride comfort and

maintainability.

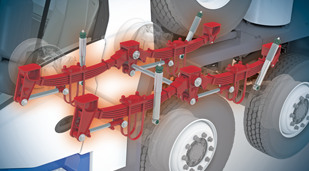

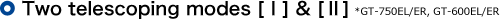

The rounded boom is made of high tensile steel which decreases its weight

while increasing its strength to realize smooth and powerful crane operation,

while the high-performance AML-C assists with safe and comfortable operation.

In addition, the newly developed Smart Chart expands workability

into whole new areas to improve operation efficiency.

The rounded boom constructed of high tensile steel contributes to decreased boom weight and increased boom strength.

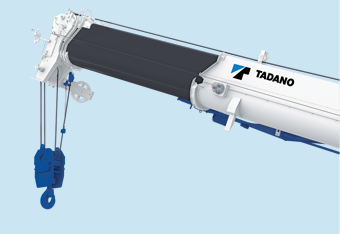

The operator can select either of the two boom telescoping

modes based on the designated job plan. This provides

enhanced crane capabilities in accordance with work needs.

Mode [Ⅰ] is extension of 2nd section

only. Then synchronized extension

of 3rd, 4th and 5th sections.

Mode [Ⅱ] is synchronized extension

of 3rd, 4th and 5th sections. Then

2nd section independently.

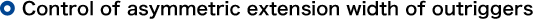

Tadano’s new AML-C is easy to use. It allows the operator to simultaneously monitor: boom angle, boom length, operating pressure of the elevating cylinder, the extension width of outriggers, slewing position, rated lifting capacity and present hook load.

All of this enables the AML-C to move easily through lifting capacity changes without changing configurations and codes to make a lift.

The AML-C provides both audio and visual warnings when a condition exists that will overload the crane and automatically employs our slow stop function to avoid shock loads.

The AML-C with “OPERATOR” pre-set working range limits and automatic slow stop functions will assist the operator to deliver safe smooth operations.

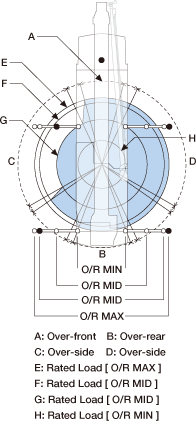

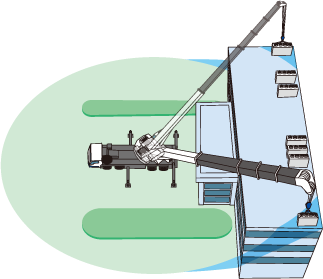

When operating the crane with the asymmetric outriggers extended, the AML-C detects the extension width of all of the crane's outriggers (front, rear, left and right) to measure maximum work capacity in each area.

When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C detects the motion and displays the maximum capacity according to the extension width of each of the outriggers, and brings the motion to a slow stop before it reaches the maximum capacity.

Regardless of operator awareness, the AML-C's slow stop function will help to minimize any safety risk.

Tadano's new Smart Chart taps into a crane's full potential

by expanding the rear part of the conventional circular work area

into a square for increased load radius when the outriggers are

extended to improve safety and efficiency.

* The above figures differ according to the type of a crane used and its operating conditions.

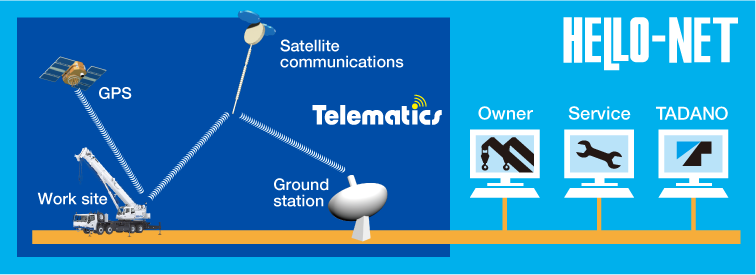

The HELLO-NET System is used to monitor crane activity straight from your computer or mobile device.

You have the ability to view work history, machine position data and maintenance information.

HELLO-NET provides advanced customer support between the owners' site and TADANO Group.